REMELTED LEAD / LEAD BLOCKS

BSpL imports Remelted Lead Ingots/ High Antimony Lead Ingots/ High Tin Lead Ingots and Blocks composed of (98%-99%) Lead Metal with remaining impurity upto (1%-2%) max. which includes Iron, Copper Tin, Bismuth Arsenic, Antimony etc.

Pyrometallurgical process is adopted to extract Refined/Pure Lead from Remelted Lead ingots/ Lead scrap. The Lead ingot generated from this refining process is of minimum 99.97% pure by weight but most offen the purity level of 99.98 % is atained. Our plant has three Refining Pots with a range of capacity between 25-35 MT.

We are expertise in producing different kinds of Lead Alloys i.e. Calcium, Tin, Selenium, Antimonial , Arsenic etc. These alloys are used in for making Automotive/Tubuler/SMF/VRLA battery plates and small parts in HD batteries, also in COS Fusion. We are equiped with various capacities of Alloying Kettle pots ranging from 5-30 metric tones per batch accompanied with high effeciency Piped Natural Gas (PNG) burners equiped with preheating arrangements.

We manufacture strictly as per the given specifications by the customer.

Red lead camically known as Lead tetra-oxide (Pb3O4) and is a soft orange or redish in color. Being insoluble in water and alcahol, Red Lead is largely used by paint industry as it helps in protecting iron and steel products from rusting.It is also an important eliment used in producing batteries, red pigments and lead glass.

Barton machine and Red Lead furnaces are used to generate the Red Oxide powder. Refine Lead ingots of minimum 99.98% purity level is required as a main input.

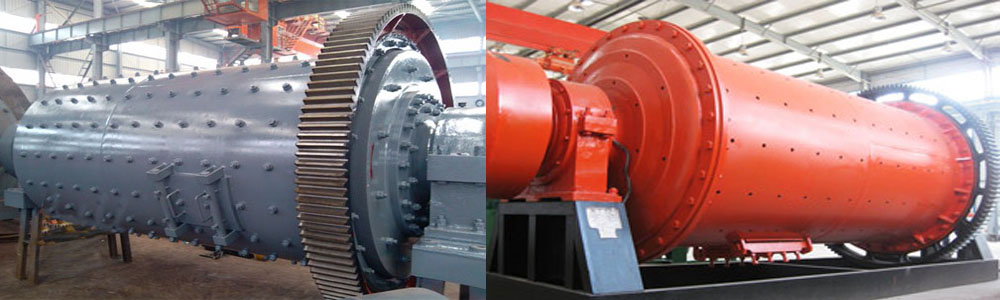

Our plant has two Barton machine three Red Lead furnaces Pots with capacity of 3 MT each. The desired quality such as the free Lead content, apparent density, partical size etc is properly examined by our experts.Lead Sub-Oxide/Grey Oxide (2PbO.Pb), a combination of Metallic Lead and Lead Monoxide. It is largely used in manufacturing plates of Lead Acid Batteries. It is produced by using Refine Lead of minimum 99.98% purity level throuh exothermic reaction process in Ball Mill.

The desired quality such as the free Lead content, apparent density, partical size etc is properly examined by our experts. We are expertise in making LSO powder up to 350 mesh.

Litharge/Yellow Oxide camically known as Lead Mono-oxide (PbO) and is yellowish in color. Litharge is extensively used by manufactures of Stabilizers. It is also been used in paint industries, Lead glass industries. Litharge is also an impoetant ingredient used by industries such as rubber industries, lubricant industries, PVC industries etc.

Barton machine and Litharge furnaces are used to generate the Lead Monoxide/ Litharge. Refine Lead ingots of minimum 99.98% purity level is required as a main input.

Our plant has two Barton machine one Litharge furnaces Pot with capacity of 3 MT

The desired quality such as the free Lead content, apparent density, partical size etc is properly examined by our experts.